A sleeve is fitted at the bottom of these balls and it can move up and down as per the movement of balls of governor. Isochronous These units offer 0 percent droop constant engine speed from no load to full load.

Mechanical constant speed governor earlier engines 5.

3 types of governor used to control engine speed. As demanded by variation of load so the engine speed is maintained nearly constant. The governor can be classified into the following types. These are given below 1.

Centrifugal governor a Pendulum type watt governor b Loaded type governor i Gravity controlled type Ø Porter governor Ø Proell governor Ø Watt governor. Variable-speed or all range governors that are designed to control the speed of the engine regardless of the throttle setting. Other types of governors used on diesel engines are as follows.

Constant-speed intended to maintain the engine at a single speed from no load to full load. A Centrifugal Governor has a simple design. This type of governor has multiple masses known as governor balls which rotate at the distance from the axis of a shaft and driven through suitable gearing from the engine crankshaft.

It has two balls of equal masses attached to the arm. So that the engine speed will be increased to its mean speed. This is how the centrifugal governor works to govern the fuel supply and regulates the mean speed of the engine when there is a variation in the load.

There is another type of governor based on the inertia principle. But these centrifugal governors are most widely used due to their easy principle. Two main types of governor are following 1.

Inertia governor Centrifugal governor Centrifugal Governor detects change in speed with the help of gear and flyweight. This Governor balance the centrifugal force of the rotating Ball by equal and opposite radial for controlling force. Flyweight helps the Governor change in speed.

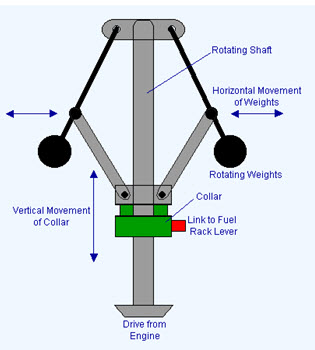

A pictorial representation of how a mechanical governor looks is given. Mechanical type of governor takes drive directly from the engine. There are two balls fitted on the main spindle and they are free to move radially.

A sleeve is fitted at the bottom of these balls and it can move up and down as per the movement of balls of governor. Woodward Governor Engine speed is mechanically controlled by centrifugal governor. Governor receives analog input signals from controller.

Speed Sensor Magnetic sensor that supplies information to the Woodward controller. A Boulton and Watt Rotative Engine made in 1797. The Watt type Governor can be seen at the top of the picture.

A change in load on a engine will almost certainly lead to a change in speed and the Governor is required to alter the supply of energy to. Woodward hydraulic-mechanical governors provide reliable and precise control of engine speed and output in virtually every type of engine application. Woodward governors are used in power generation marine pump compression and vehicle applications.

A propeller governor is used to sense propeller and engine speed and normally provides oil to the propeller for low pitch position. Figure 1 There are a couple of nonfeathering propellers that operate opposite to this. Fundamental forces are used to control blade angle variations required for constant-speed propeller operation.

Your small engine contains either a mechanical governor pneumatic governor or an electronic governor. The main difference between the three are how they detect speed. How Mechanical Governors Work.

Change in the speed of the engine is utilised for movement of the governor sleeve. One of this type of governors is shown in Figure 51. These governors are commonly used because of simplicity in operation.

Inertia and Flywheel Governors In these governors the inertia forces caused by the angular acceleration of the. To control engine speed a mechanical governor uses gears and flyweights inside the crankcase to detect changes in the load and adjusts the throttle accordingly. If youre operating your small engine under a light load the carburetor needs to deliver a relatively small amount of air-fuel mixture to the combustion chamber.

Detroit diesel engines use both mechanical and hydraulic governors on the engines of the following type. Mechanical limiting speed governor 2. Variable mechanical speed governor 3.

Variable low-speed limiting speed mechanical governor 4. Mechanical constant speed governor earlier engines 5. Dual-range limiting speed mechanical governor 6.

Our governors are used worldwide to provide reliable and precise control of speed and output in power generation marine pump compression and vehicle applications. Woodward also provides global support through an extensive network of AISFs Authorized Independent Service Facilities that have been trained by Woodward to support governors in every corner of the world. Many of these AISFs also have the.

A centrifugal governor is a specific type of governor with a feedback system that controls the speed of an engine by regulating the flow of fuel or working fluid so as to maintain a near-constant speed. It uses the principle of proportional control. Centrifugal governors were invented by Christiaan Huygens and used to regulate the distance and pressure between millstones in windmills in the 17th century.

Features of an Electronic Speed Control. As we know an ESC controls the speed of the motor spin of an airplane. It helps a similar purpose as the throttle servo of a glow-powered airplane.

It is an edge between the radio receiver of an airplane and the power plant. Electronic speed control will have 3- sets of wires. There are three types of governors in the small engine market.

Pneumatic mechanical and electronic. Small engines are lawnmowers pressure washers etc with engines in the 100 cc-1000 cc size. Lawnmowers may have a lever to control engine speed manually or a pneumatic governor for constant RPM.

Adjustable-speed drives ASDs By far the most commonly-used AC motor control method is the use adjustable-speed drives. In most commercial and industrial environments these have supplanted virtually every other motor speed control method. An adjustable-speed drive works on the principle of varying the frequency to vary the speed of the motor.

The percent increase in speed to no load speed would remain the same. Many applications easily accept some speed droop which means a less costly and complex governor can be used even if the gen set will be paralleled with other units. Isochronous These units offer 0 percent droop constant engine speed from no load to full load.