When cad cell senses no flame safety switch heater begins heating through the electronic network. If the control does not start when T-T is jumpered there is no power to the primary control or the cad cell may be shorted.

Cad cell is seeing external light is defective or cad cell connections are shorted.

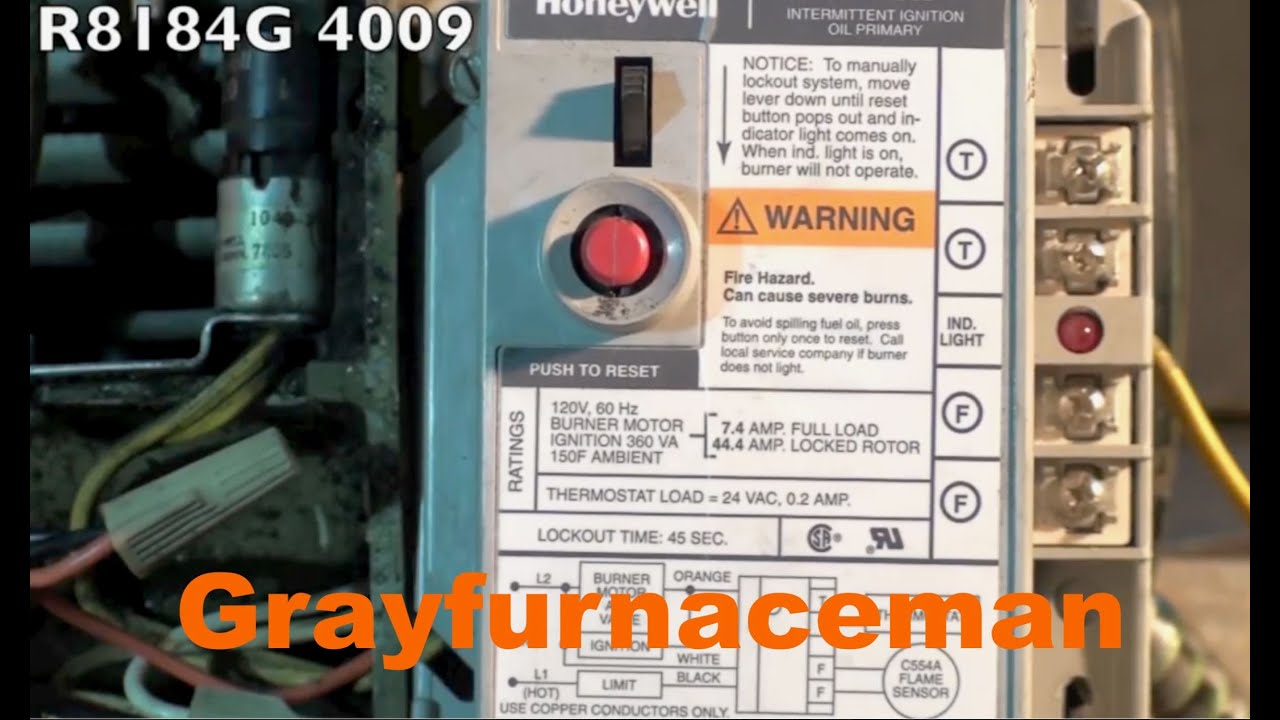

Cad cell relay wiring. This one covers how to wire a replacement cad cell relay for the oil furnace. This video is part of the heating and cooling series of training videos made t. The cad cell itself that is the little cell that sees the oil burner flame is wired often by a yellow wire to the cad cell relay switch see photo which is usually a gray box with a red reset button located on top of or alongside the the oil burner assembly.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. And meets their If cad cell leads are run with line voltage wires breakout knockout at the. Disconnect power supply before connecting wiring.

Be sure combustion 2 - Typical hookup for the RG cleaned by spraying with Honeywell. WIRING DIAGRAM - UPFLOWHORIZONTAL WIRING DIAGRAM - downflow 29 NOTE. The Honeywell RG may be used in place of the RA.

Troubleshooting a Relay if the burner starts and then locks out. Check for line voltage at the black and white wires. Disconnect one thermostat lead from T-T and place jumper across T-T terminals.

Disconnect the cad cell leads from F-F terminals. Connect one lead from a 1500 ohm resistor to one of the F-F terminals. USD and it simply plugs-in to a socket on the end of a wire that connects to the cad cell relay control.

So replacing it during service is a trivial step. Many service techs try to repair a problem by replacing a lower-cost easy-to-replace part as that can be less costly to. Wiring Wiring must comply with local and national electrical codes and with the wiring diagram.

Individual or bundled neutrals may be attached to any L2 terminal. Field checks 1Safety timing TFI test Remove one CAD cell wire F-F. The control should lockout within the TFI time limit.

Replace CAD cell wire. Wiring Wiring must comply with local and national electrical codes and with the wiring diagram. Individual or bundled neutrals may be attached to any L2 terminal.

Field checks 1Safety timing TFI test Remove one cad cell wire F-F. The control should lockout within the TFI time limit. Replace cad cell wire.

Cad Cell keeps Tripping. My problem is that the red trip switch keep triggering. I have replaced the following.

I have done a total cleaning and set the spacing of the electrodes and nozzle pump bled. The cad cell is clean and checks out on ohms meter. Flame is clear and bright thru eyeglass.

Factory wiring field wiring factory tubing 2 square low profile electronic this series of control sequences provides single duct variable air volume cooling with up to three stages. Changeover contactor wiring diagram. Focuspro th5220d non programmable digital thermostat 3 remove the wallplate from the ther mostat as shown at leftthen follow directions below for mounting.

CHECK CAD CELL 1Disconnect power at system switch circuit breaker or fuse. 2Clean cell face with soft cloth. 3Make sure cell is seated securely in socket.

Be careful not to disturb socket position. 4Reconnect cad cell leads to F-F terminals. 5Reset safety switch turn on power and set thermostat TRIP SAFETY SWITCH BEFORE PERFORMING BURNER MAINTENANCE.

When cad cell senses no flame safety switch heater begins heating through the electronic network. After approximately 1 5 30 or 45 seconds depending on model the safety switch opens de-energizing relay 1 K. Indicator light if provided comes on.

Contacts 1K2 open shutting off the burner motor oil valve and ignition. Cad cell is seeing external light is defective or cad cell connections are shorted. Go to step 3.

Eliminate external light source or permanently shield cad cell. ION BURNER DOESNT START Trouble is in cad cell or oil primary. Go to step 2.

Check all wiring connections. Load relay contact ratings. Cad cell leads line voltage leads mounting screw hole red reset button ventilation slots 4 x 4 junction box hole or knockout for cad cell leads low voltage terminal strip 1 strip wires 38 in.

Insert from side above or below. Control starts then check the wiring connections between B1-B2 and T-T and on the plug in relay board. If the control does not start when T-T is jumpered there is no power to the primary control or the cad cell may be shorted.

9 To check for possible shorted cad cell or cad cell wiring remove one lead from F with T-T jumpered. The Beckett GeniSys Advanced Burner Control is a 120 VAC primary safety control for residential and light commercial oil burners used in boiler furnace and water heater applications. The GeniSys is used with a suitable cad cell flame sensor to control the oil burner motor igniter and optional solenoid valve.

Kwik-Sensor CAD Cell Relay 2-Wire. 0 View More Info. Kwik-Sensor CAD Cell Relay 2 or 3-Wire.

11 Add To Cart. Kwik-Sensor CAD Cell Relay 2-Wire. 7 Add To Cart.

668 Series Kwik-Sensor CAD Cell Relays. Honeywell r8184g4074 cad cell relay 30 sec replaces r8184g1179 13250. Honeywell r8184g4082 cad cell relay 45 sec w alarm cont 13250.

Honeywell r8184m1051 cad cell relay with y g terminals for cooling 45 s. Honeywell r847a1085 dpst or spst heavy duty relay 2-wire connection. Honeywell r856b1002 enclosed fan control.

Honeywell R8184M1051U Cad Cell Relay. This fits your. Make sure this fits by entering your model number.

Intermittent ignition is on while the burner is on. Solid state flame sensing circuit. Place a jumper across cad cell terminals.

Follow procedure to turn on burner. Burner must not start indicator light turns on and control remains in Idle Mode. Follow procedure to turn on burner.

Close hand valve in oil supply line. Device enters recycle mode. Device tries to restart system after approximately 60 seconds.

ELEMENTARY DIAGRAM CONNECTIONS WIRE NUMBERING. ANSIIEEE Standard Device Numbers. 1 - Master Element 2 - Time Delay Starting or Closing Relay 3 - Checking or Interlocking Relay 4 - Master Contactor 5 - Stopping Device 6 - Starting Circuit Breaker 7 Rate of Change Relay 8 - Control Power Disconnecting Device 9 - Reversing.

Wiring The power or hot lead from the limit control is connected to Terminal 1. All neutrals are connected to Terminal 2. One wire from the burner motor and one from the oil valve if used are connected to Terminal 3.

If the unit operates as interrupted duty ignition one wire from the trans-former is connected to Terminal 4.