How To Flush Ac System After Compressor Failure The Best Tutorials How To Flush Ac System After Compressor Failure. Here is a compressor motor.

Blow out each part and pipe one by one with nitrogen.

How to flush ac system after compressor failure. How To Flush AC System After Compressor Failure There are a few specialized items needed to perform a successful AC system flush. A pressure cylinder is a primary tool needed for the procedure. This is a metal cylinder with an air fitting or Schrader valve on top and a hose on the bottom.

Use flushing liquid. Instead of using a cleaning solvent you can also use a flushing liquid like a chemical- or water-based fluid. This process works better R1234yf air-conditioning systems and for the systems being converted to R134a from R12.

You must use nitrogen to dry the components after finishing the cleaning. Blow out each part and pipe one by one with nitrogen. These are the ways how to flush AC system after compressor failure.

Blow out each part and pipe one by one with nitrogen. These are the ways how to flush the AC system after a compressor failure. Flushing is done to remove not only substantial buildups from the AC unit.

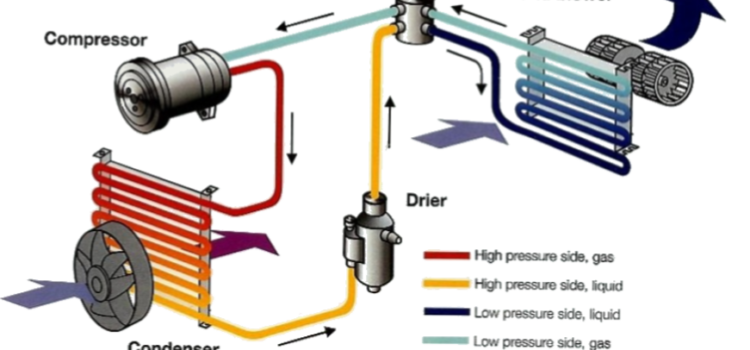

But also dirty liquid and lubricating oil residue. Flushing the system to eliminate these contaminants helps prevent damage to or seizing of the new compressor as well as the other existing parts of the system. An AC system flush involves running a liquid solvent through the unit with vacuum pressure to clean the inside components of the system.

The AC compressor must be lubricated at all times because it is a moving part however the oil is circulated throughout the entire system. How to flush ac system after compressor failure. An ac system flush is a necessary procedure to ensure the air conditioning system is clean and free from any contaminants.

Stay away from alcohol based products for ac flushing. Flushing is the only way to really get the majority of oil debris and contamination out of the system. How To Flush Ac System After Compressor Failure The Best Tutorials How To Flush Ac System After Compressor Failure.

De-energize all of the electrical leads and ensure they are safely positioned. The common causes of air conditioner compressor problems are. After the flushing process the system must be dried with nitrogen.

After the drier is opened it should be installed and the ac system must be vacuumed down within 45 minutes. If the compressor clutch is the source of compressor replacement. If this is the case youll probably need to replace it.

Pour the chosen solvent or flushing liquid into each component and then blow in each direction with shop air. The cleaning is finished when no more debris is blown out the solvent or flushing liquid is. If a new compressor is placed in a dirty refrigerant system the new compressor will suck in loose contamination particles and eventually fail quickly.

Inspect the oil and expansion devices for signs of grit or foreign particles. If foreign particles are present it is imperative that the system is fluid flushed. If your system was still functional before you removed the compressor that could be a good sign.

Receiverdryer and expansion valve. The parts would include compressor receiverdryer mandatory flush es possibly the condenser and possibly a filter. For that reason you should always flush the AC system with a special cleaner whenever you replace a failed compressor.

Its also a good idea to replace the orifice tube or screen when you have a compressor failure. Some new compressors come with these parts in a kit. Cleaning the oil and oil film inside the components will avoid all of the contamination from the AC system.

Remove the old oil remove the contamination. Always flush the AC system whenever you replace or remove the AC compressor or whenever there is any contamination in the system. Every time remove and inspect the orifice tube.

From the orifice tube you can see the AC systems condition. This strategy has been used in turbines but be sure to check its suitability for your compressors. Contaminant Concentration and Location.

If the contaminant concentration is high or risky for the application first open the machine and clean it manually. After the machine has been reassembled perform an oil flush. In this MAHLE installation video learn why and how a car air-conditioning system is flushed.

Subscribe to the MAHLE Channel. An experienced auto technician in a shop is able to flush every part of the cooling system that is not being replaced with an approved AC flush solvent. This is done after the diagnosis of the compressor shows that it failed due to an external item on the compressor.

After removing all of the parts and they are all flushed the technician can. An AC flush in simple terms is the act of using compressed air to send a solution through the AC system which cleanses and grabs any contaminants and particles and flushes them out of the system. An AC flush is only performed when the system is opened or when a major component like the AC compressor is changed out.

The goal is a clean and dry components leaving residual flush in the system will dilute the oils and possibly cause a future compressor failure and many other theoretical problems. The Procedure is to chemically flush the heat exchangers Evap. Cond only possibly with hoses attached.

Here is a compressor motor. Notice that when a mild burnout occurs only one spot on the windings is burned. A severe burnout is when the contaminants are pumped through the refrigerant system before the motor stops.

This type of burnout is not confined to one small spot on the windings as you can see here. Flushing with flushing liquid. In this method the air-conditioning system is cleaned with a special flushing liquid in combination with compressed air.

After the flushing process the system must be dried with nitrogen. This method is especially well suited for converting from R12 to R134a and is compatible with R1234yf air-conditioning systems. How an Air Conditioning Flush is performed.

A technician will connect the manifold gauges to the proper fittings. A specialized machine will begin to evacuate the system until the pressure drops to 0 psi. Once the pressure is reduced the vehicle is ready for the next step.

The technician will then remove the refrigerant hose from both the high. For these reasons you should always flush the AC unit to remove the metal particles and other solids whenever changing the failed compressor. Even with the expensive R1234yf air-conditioning refrigerant chemical flushing is a cost-effective alternative.

Nitrogen must be used to dry the system after flushing with the flushing liquid.